IR Fast Medium Wave (1500-2200K)

Products - Light Sources

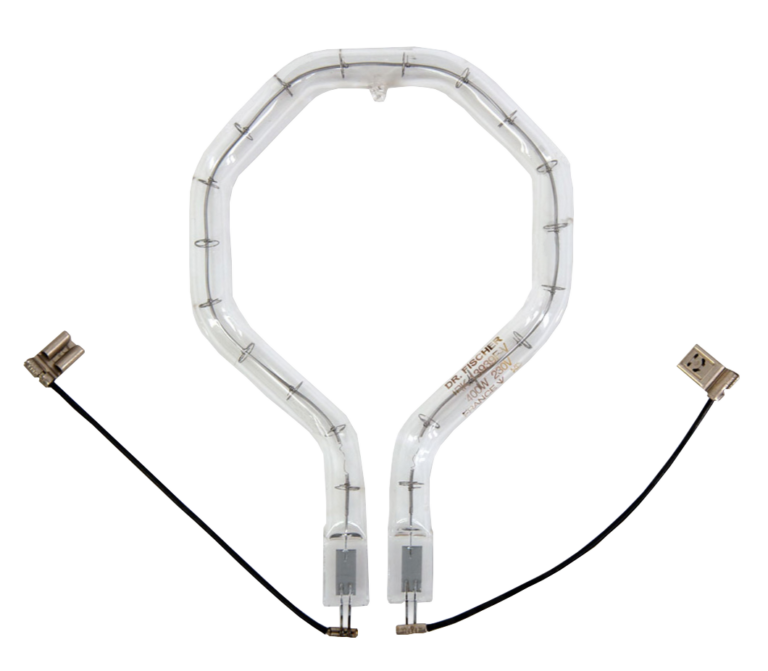

Fast Medium Wave Infrared Heating Emitters

Fast medium wave (FMW) infrared heaters offer an excellent balance between rapid response and efficient heat transfer. They warm and cool quickly, enabling strong process control and minimizing energy loss during pauses. Their wavelength is particularly well absorbed by materials such as water and various plastics making them ideal for drying, forming, preheating, printing, coating, and textile applications.

Additionally, FMW emitters often provide a more uniform heat distribution compared to short-wave infrared, supporting stable product quality even in demanding processes.

Key Advantages of IR Fast Medium Wave (1500-2200K)

Efficient heat transfer into moisture-rich & plastic materials

High absorption efficiency improves heating performance.Quick heating & cooling

Supports precise temperature control and reduced energy waste.Stable & uniform heating pattern

Ideal for processes requiring consistent thermal distribution.Flexible integration

Available in single and twin tube versions for various system layouts.Industrial-grade durability

Designed for continuous, high-performance operation.

IR Fast Medium Wave (1500-2200K) from DR. FISCHER Europe

Key Facts of IR Fast Medium Wave

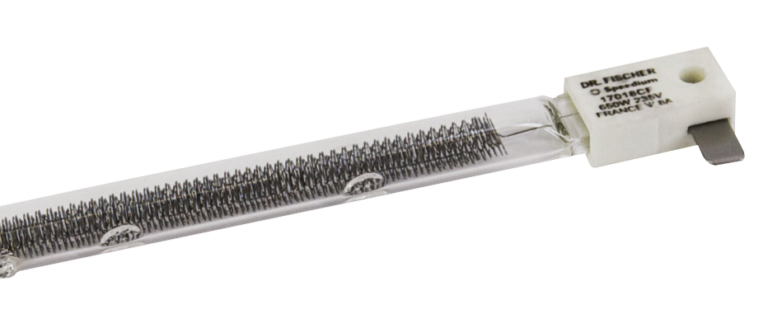

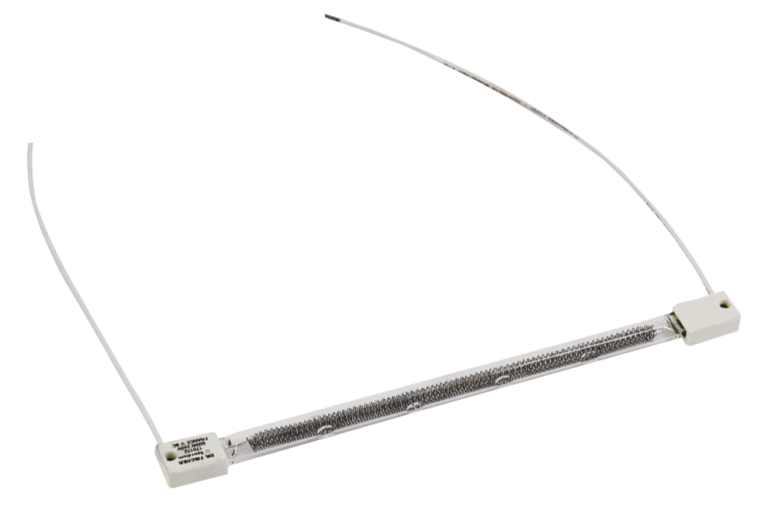

Fast medium wave emitters from DR. FISCHER are available with coil temperatures between 1700 K and 2100 K, with customizable dimensions to match specific machine requirements. Tube designs include twin and single options, ranging from 10 mm to 16 mm in diameter. Heating lengths reach up to 5000 mm for twin tubes and up to 1600 mm for single tubes. With power densities around 80 W/cm and maximum power above 20 kW (depending on size and voltage), these emitters deliver a strong and reliable thermal output for a broad temperature range.

Specifications of IR Fast Medium Wave

DR. FISCHER fast medium wave emitters are available in single or twin tube execution. Single tubes reach up to 1600 mm in length, while twin versions extend up to 5000 mm to support larger process zones. A maximum current of 20 A allows high-power operation, making them suitable for continuous industrial workloads where efficient and precise heating performance is essential.

Specifications

| Feature | Specification |

|---|---|

| Color temperature of the coil (K) | 1700 K – 2100 K |

| Tubes (section in mm) |

1) 33 × 15 (twin) 2) 23 × 11 (twin) Single tubes from 10 mm to 16 mm diameter |

| Heating length (mm) |

5000 mm (twin) 1600 mm (single) |

| Power density (W/cm) | 80 |

| Max length single tube (mm) | 1600 |

| Max length twin tube (mm) | 5000 |

| Max current (A) | 20 |

| Max power | Above 20 kW depending on length and voltage |

| IR reflectors | ||||||

|---|---|---|---|---|---|---|

| Reflectivity | Durability | Cost | Radiation orientation | Main advantages | Main drawbacks | |

| Gold | ☆☆☆☆☆ | Bad | €€€€€ | Specular | - Best reflectivity - No thermal inertia |

- Low temperature resistance (<600°C) - High cost |

| White ceramic | ☆☆☆ | Very good | €€ | Diffuse | - Good price-performance ratio | - Reflectivity 10 to 15% lower than gold |

| MLRI | ☆☆☆☆ | Very good | €€€ | Diffuse | - Reflectivity between the white ceramic and gold | - Slightly more expensive and slightly less stable than white ceramic |

| LRP | ☆☆☆☆ | Excellent | €€€€ | Specular | - Reflectivity close to gold - Auto-cleaning - Longer lifespan than all other reflectors |

- Expensive to start with (but no need to replace it with the lamp) - Thermal inertia |

| Highly reflective aluminum | ☆☆☆ | Good | €€€ | Specular or diffuse (depends of the finish) | - Can be combined with other reflectors | - Added piece → takes more space |

Typical Applications of IR Twin Lamps:

Drying and Curing

Fast and efficient curing of coatings, adhesives, inks, and varnishes in industrial processes.Plastic Forming and Shaping

Precise and uniform heating of thermoplastic materials for forming, bending, and welding applications.Food Industry Processes

Controlled infrared heating for baking, browning, drying, and sterilization in food production.Textile and Paper Industry

Rapid drying of inks, coatings, and finishes on textiles and paper surfaces.Electronics and Semiconductor Manufacturing

Targeted heating for bonding, soldering, and component processing with high accuracy.Surface Treatment and Coating

Enhanced curing and drying of paints, lacquers, and industrial coatings with minimized heat loss.

By leveraging the efficiency and flexibility of IR Twin Lamp technology, you can achieve faster process times, reduced energy costs, and reliable results across a wide range of industrial heating applications.

Selected Examples from Our IR Shortwave + NIR (2200-3200K)

STELA 17017CF 800W 240V

VITAE 14181Z 300W 120V